CNC Routing

CNC Milling

CNC Turning

Laser Cut /Engrave

MULTIPLE SOFTWARE & CAPABILITIES

Master CAM

Auto CAD

Solid Works

Build only of details, fixtures, and gages

Prototype as well as production runs

Reverse engineering of fixtures, special machines & detail work

We also do special fixtures and machines

The first CNC machines were developed in the 1940s and 50s and relied on a common telecommunication data storage technology known as “punched tape” or “perforated paper tape.” Punched tape technology is long obsolete as the data medium quickly transitioned to analog and then digital computer processing in the 1950s and 1960s.

How it Works: Machining in general is a way to transform a stock piece of material such as a block of plastic and arrive at a finished product (typically a prototype part) by means of a controlled material removal process. Similar to the other prototype development technology, FDM (3D printing), CNC relies on digital instructions from a Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) file like Solidworks 3D. The CNC machine interprets the design as instructions for cutting prototype parts. The ability to program computer devices to control machine tools rapidly advances shop productivity by automating the highly technical and labor intensive processes. Automated cuts improve both the speed and the accuracy with which prototype parts can be created - especially when the material is critical (such as is the case with polypropylene - read more about polypropylene).

Oftentimes machining processes require the use of multiple tools to make the desired cuts (e.g. different sized drill bits). CNC machines commonly combine tools into common units or cells from which the machine can draw. Basic machines move in one or two axes while advanced machines move laterally in the x, y axis, longitudinally in the z axis, and oftentimes rotationally about one or more axes. Multi axis machines are capable of flipping parts over automatically, allowing you to remove material that was previously “underneath.” This eliminates the need for workers to flip the prototype stock material and allows you to cut all sides without the need for manual intervention. Fully automated cuts are generally more accurate than what is possible with manual inputs. That said, sometimes finishing work like etching is better accomplished by hand as well as simple cuts that would require extensive design work to program the machine for automation.

CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) software.

is used extensively throughout the furniture making industry. CAD is a software package that assists the programmer to draw and design the product while CAM is a software package that assists the operator to run the CNC machine. CAD and CAM work together as a system. This means that a drawing done in CAD will automatically be configured in CAM. Before the integration of a CAD/CAM system, CAM had to re-create the model produced by the CAD system before it could create a program. Now, once the machining operations to be performed are specified by the operator CAM will automatically create the CNC program.

When using a CAD/CAM system the programmer is able to:

do all the programming on the computer,

run a simulation on the screen to prove that the program works, and

download the proven program to the CNC machine.

The operator is then able to specify the machining operations required and the CAM system will integrate these into a CNC program.

Also, the link between CAD/CAM software and CNC machines increases productivity by:

automatically translating the designs into instructions for the computer controller on the machine tool, and

enabling programs to be modified for use on other jobs with similar specifications.

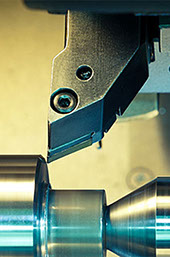

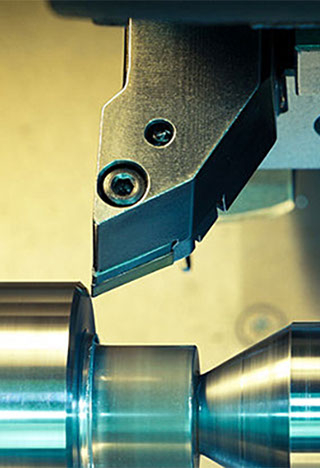

Turning is a machining process in which a cutting tool,

typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. The tool's axes of movement may be literally a straight line, or they may be along some set of curves or angles, but they are essentially linear (in the non mathematical sense). Usually the term "turning" is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (that is, holes, of one kind or another) is called "boring". Thus the phrase "turning and boring" categorizes the larger family of (essentially similar) processes known as lathing. The cutting of faces on the workpiece (that is, surfaces perpendicular to its rotating axis), whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset.

Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other types of machining besides turning.)

When turning, a piece of relatively rigid material (such as wood, metal, plastic, or stone) is rotated and a cutting tool is traversed along 1, 2, or 3 axes of motion to produce precise diameters and depths. Turning can be either on the outside of the cylinder or on the inside (also known as boring) to produce tubular components to various geometries. Although now quite rare, early lathes could even be used to produce complex geometric figures, even the platonic solids; although since the advent of CNC it has become unusual to use non-computerized toolpath control for this purpose.

The turning processes are typically carried out on a lathe, considered to be the oldest machine tools, and can be of four different types such as straight turning, taper turning, profiling or external grooving. Those types of turning processes can produce various shapes of materials such as straight, conical, curved, or grooved workpiece. In general, turning uses simple single-point cutting tools. Each group of workpiece materials has an optimum set of tools angles which have been developed through the years.

Here’s the big picture: A CNC is a digitally controlled router that cuts from its highest to its lowest point in three dimensions over the entire area of its bed. What would any woodworker do with that capability? It turns out you can do quite a lot. Below are some of the things I use a CNC for in my woodworking shop. Obviously, these are simple examples and they’re also potential topics for future articles and blog posts. There’s a lot to cover.

CNC Woodworking

As mentioned before, I’ve been using a CNC to cut patterns for a long time using an outside CNC services to do the work. It works great. If you’re willing to do the needed 2D CAD or even Adobe Illustrator drawings, I can’t recommend it enough. Perfect patterns.

CNC Milling

I flatten and surface boards that would be too awkward or large for a jointer. I thickness plane boards that can’t fit through my planer. CNCs have been a great tool for working on large slabs of wood.

Use the Built-in Precision

I take advantage of CNCs high level of precision for certain needs. Even simple tasks sometimes need precision. For example, if I need a series of holes that need to be precisely laid out and sized, the CNC sometimes does this better than other techniques.

CNC Turning

Part making is probably the best use of a CNC in a woodworking shop. And it’s a straightforward process once you learn how to do it. I regularly use a CNC to cut wood parts, except for the rectilinear parts — if you have the tools, it’s just easier and faster to use a table saw and miter saw for parts with straight lines. The results from cutting CNC parts are even more accurate then I’ve gotten with patterns and shaping. And, because the tool is machining a rigidly held board, I can cut even the most delicate of details without breaking the wood. Bonus: sometimes the CNC is a great assistant. While the CNC is cutting parts I can be working on something else.

Manufacturing

The CNC has been great for adding details to woodwork. I use what’s referred to as engraving routines to add cove cuts, bevels, grooves or other precision detail that normally might have to be carved into parts. Certainly hand tools can do this but there are some situations where the added precision and control is a real advantage. It’s also a great tool for adding lettering, figures to panels and other carving details.

CNC Routing

I use a CNC for some kinds of joinery that would be difficult to do accurately in other ways. I regularly use two techniques/tools for mortise-and-tenon joinery (Leigh FMT or Domino) and sometimes a mortiser. As great as these tools are, sometimes they can’t accurately put a mortise right where you need it. On the edges or ends of a board is usually not a problem. But, in the middle of a larger surface is challenging. The CNC puts a joint anywhere you like. That’s very handy.

Another example of how I use a CNC as a joint making tool is a kind of a twofer. If you’re already using the CNC to cut parts that ultimately need mortises, why not just cut the mortises at the same time?

Finally, a CNC router offers the potential for kinds of joinery we’ve never seen before. No matter the tool or method, we’ve been doing joinery pretty much the same way for thousands of years successfully. The value of millennia of experience is that we know exactly why and how joints work and why they can fail. The point is we understand the engineering. So let’s apply what we know and maybe rethink the entire of idea of joinery. The possibilities are exciting and it’s something I’m seriously exploring.

Jigs and Fixture Making

I regularly use a CNC for making jig and fixture parts. It’s particularly handy if you need dedicated clamp cauls for an unusually shaped project or other task-specific tools.

Precision Machining

I know it’s a strange topic to bring up on a woodworking blog but sometimes plywood is a very useful material. Cabinets are obvious, but there’s a lot of other things you can make out of sheet goods, particularly if you have a CNC handy. I’ve made, chairs, stools, tables, tool boxes and all kinds of things with plywood. Parts are joined together with a whole range of joints developed for the task that pretty much snap into place. And, there are great plans out there for CNC owners. Many are free and well designed.

CNC Machine Shop

I had never cut aluminum or plastics before I got a CNC. Now I use it to machine aluminum for jigs that need metal parts. Same with polycarbonates and plastics. Depending on the machine’s rigidity, many machines can cut soft metals. I have friends with CNCs that use them to cut brass or aluminum parts for furniture. As you can imagine cutting metal is not the same as wood. You use different procedures, tooling and techniques.

3D Carving

I regularly use a CNC to add features that would normally be carved by hand or done with elaborate jigs or router setups. It’s great for tasks like carving a seat for a stool or a chair, tapering a bevel or a progressive round over the length of a table leg, for example. Many things are possible if you can work in 3D in CAD software and have CAM programs that support 3D operations and learn how to carve with a CNC.

Next I’ll explain how I accomplished certain woodworking tasks before I had a CNC and what’s changed since.

jcs woodworking & manufacturing

23024 Hospital St., Cassopolis, MI 49031

574-298-7463

JCS Woodworking & Manufacturing is a precision CNC machining shop providing component parts in Woods, Metals and Plastics.

Services we provide:

CNC Routing - 2D & 3D in wood and plastic

CNC Machining - Milling in metal and plastic

CNC Machining - Turning in metal and plastic

laser cutting and engraving - 2D & 3D

3D laser scanning

Today's CNC machines and solid modeling software has revolutionized the way we design and manufacture parts. We have now made this technology available to you through our custom CNC machining services. We found our wood component customers were also needing metal and plastic parts machined as well so we have added the capabilities of machining metals and plastics to our manufacturing processes. If we can be of service to you please Contact Us

Proud sponsor and mentor of FIRST Robotics!